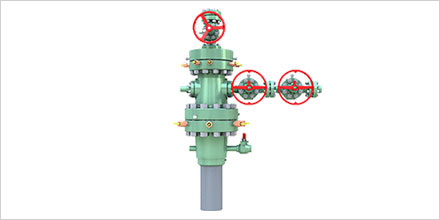

Cameron Drill Through Wellhead System

The Cameron drill-through wellhead system maximizes efficiency by streamlining drilling operations. Well control is achieved with one BOP nipple-up, resulting in safer drilling activities and providing significant time savings that reduce rig costs. Mandrel hangers eliminate the need to set slips, rough cut, and final casing cut. Rig-up and rig-down is faster, fewer personnel are required during the process, and the period of time personnel need to work under suspended loads in a confined area is kept to a minimum. Hot work during the drilling phase is not required.

Saves time spent waiting on cement

With our drill-through wellhead system, there is no waiting on cement before lifting the BOP stack. The hanger is designed with integral flutes, which allow cement returns to pass up through the BOP stack. The casing head landing joint is tailored to the specific rig kelly bushing to ensure proper elevation of the cementing head on the rig floor.

Eliminate B-section spool when drilling out for liner casing

The packoff and bit guide are run through the BOP stack, locked in place, and tested. By eliminating the need for a B-section spool when drilling out for liner casing, about 8 to 12 hours are saved.

The drill-through wellhead system is available in 11-in size with 5,000-psi or 10,000-psi working pressure.

Control ball valves

<

>

AVAILABLE BODY MATERIAL SELECTION

• CS, LTCS (*)

• Low Alloy Steel (*)

• Stainless Steel

• Ni Alloy

AVAILABLE OBTURATOR MATERIAL SELECTION

• Low Alloy Steel (*)

• Austenitic / Ferritic /

• Martensitic Stainless Steel

• Duplex /Superduplex /Ni Alloy

Product Info

Documentation

Case Studies

Training & Support

Video

How does it work?

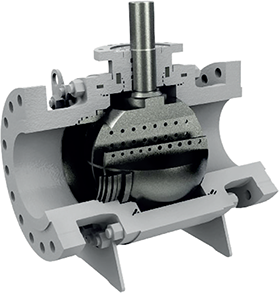

Petrolvalves control are specifically design to control flows in severe service applications, both on gas and liquids. The solid design is based on extensive campaign of numerical simulations and experimental tests. 984 Series combines high flow capacity with accurate control at small flow conditions, thus increasing valve rangeability at values once unthinkable for control valves. The side entry split body geometry offers excellent structural strength and versatility of construction, while the trunnion mounted design allows to transfer the pressure load from the trim directly on valve body, to reduce actuating torques and increase lifetime of seals.

What problems does it solve?

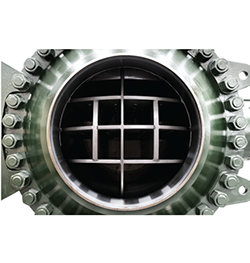

The 984 Control Valve incorporates a Multistage Cage Trim inside the ball containing plates with drilled holes, with specific design for noise reduction on gas flows, and cavitation prevention in liquid flows. Trim design allows high control capability, huge rangeability and excellent and long lasting tightness. At low openings, process fluid will go through all drilled plates inside the valve trim. This feature makes possible to handle high pressure drops by controlling low CV values

Title

Description

Actions

Title

Description

Actions

No data available in table

Title

Description

Actions

Head office

1 Adeola Odeku Street

South Atlantic Petroleum Towers

Victoria Island | Lagos | Nigeria

Tel: +234 1904 9589, +234 (0) 909 026 0055

Lagos Branch Office

15, Ogundana Street | Off Allen Avenue |

Ikeja | Lagos | Nigeria

Stay Connected With Us!

GCA Energy Staff Email

Access Email Service

Port Harcourt Branch Office

15 Emeyal Street

GRA Phase I

Port Harcourt, Rivers State, Nigeria

Tel: +234 8093906260